Maximize safety and performance with advanced Enbio S autoclave technology.

When it comes to preventing cross-contamination in a dental practice, autoclaves stand out as an essential part of the process. They effectively kill viruses, bacteria, and other harmful microorganisms on tools and equipment, keeping patients and practitioners safe. But what if there was a way to make dental sterilization significantly safer and faster?

In this article, we will take a look at how advanced Enbio S autoclave technology can dramatically cut reprocessing time and improve instrument sterilization. We will also discuss key best practices for dental instrument reprocessing and the uses and benefits of Enbio autoclave systems.

Dental equipment sterilization best practices

As a general best practice, the manufacturer’s instructions—including ideal temperatures and times—should always be followed for proper dental instrument reprocessing. The Centers for Disease Control (CDC) recommends a list of safety best practices, including always treating instruments as if they are contaminated and handling them with care. Personal protective equipment (PPE) should be worn at all times when cleaning and reprocessing contaminated tools and equipment, especially when handling sharps.

As a general best practice, the manufacturer’s instructions—including ideal temperatures and times—should always be followed for proper dental instrument reprocessing. The Centers for Disease Control (CDC) recommends a list of safety best practices, including always treating instruments as if they are contaminated and handling them with care. Personal protective equipment (PPE) should be worn at all times when cleaning and reprocessing contaminated tools and equipment, especially when handling sharps.When carrying instruments, the CDC recommends using covered, leak-proof containers strong enough to resist punctures. After the sterilization process, instruments should be left to dry thoroughly and then packaged and labeled with critical data such as the date and time, sterilizer used, cycle or load number, and expiry date, if needed. Finally, sterile instruments should be stored chronologically in a clean and dry environment and be used on a first in, first out (FIFO) inventory rotation.

While there are many autoclaves on the market, a primary best practice is to select the solution that thoroughly sterilizes dental instruments without wasting space or time in a busy practice. Achieving faster time-to-sterilization will also reduce any reprocessing bottlenecks for quicker operatory changeovers and shorter patient wait times.

Uses and benefits of the Enbio S Autoclave

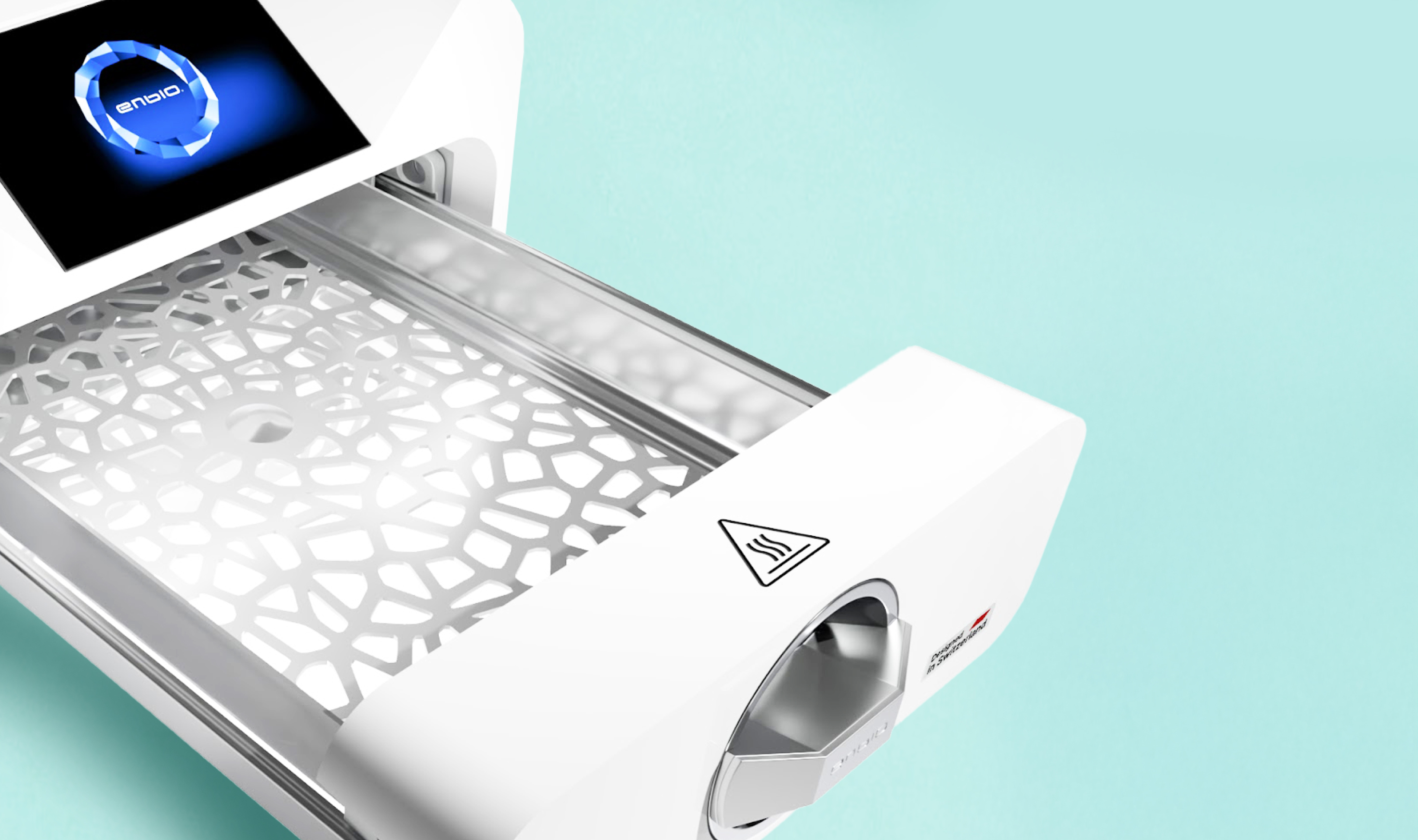

Providing faster, safer sterilization of dental instruments every time, the Enbio S Autoclave is a Class B solution (the highest class of steam sterilizers), featuring a compact footprint and lightweight design. Ideal for a variety of dental and medical applications, it processes and dries instruments up to four times faster than other autoclave technologies.

The Enbio S Class B Autoclave employs a sophisticated system of steam and pressure to sterilize all tools in the chamber. Its vacuum pump removes all the air, which enables the steam to penetrate deeply into the load and access any hollows and pores in the tools. Effective for sterilizing wrapped and unwrapped instruments, the Enbio solution provides maximum sterilization while the vacuum cycles reduce overall processing time. Moreover, the Enbio S Class B Autoclave packs all this power into a small footprint that saves valuable space in a dental practice. Up to six times smaller and three times lighter than other autoclaves on the market, it delivers speed and efficiency in a compact tabletop design.

For added convenience, the Enbio S Autoclave can also be plugged into any outlet for operation. And since it draws distilled water from an external tank, there is no need to place it near a water connection. To facilitate record keeping and data archiving, the Enbio S automatically saves processing data onto a USB stick. Its proprietary software also provides printable sterilization reports in easy-to-read graphs that simplify data analysis.

For added convenience, the Enbio S Autoclave can also be plugged into any outlet for operation. And since it draws distilled water from an external tank, there is no need to place it near a water connection. To facilitate record keeping and data archiving, the Enbio S automatically saves processing data onto a USB stick. Its proprietary software also provides printable sterilization reports in easy-to-read graphs that simplify data analysis.A highly effective autoclave, the Enbio S has FDA 501(k) clearance and has been comprehensively reviewed for safety and performance. It provides powerful, efficient sterilization for peace of mind and improved patient flow.

Conclusion: Enbio S technology optimizes sterilization time and safety

The American Dental Association (ADA)reports that the dental sterilization market is on the rise. A ten-year forecast expects the market to reach up to USD 2.7 billion globally by 2032, up from USD 1.4 billion in 2022. Advances in Class B autoclaves are providing safer and faster solutions. And while equipment sterilization should never be rushed, leading-edge Enbio S autoclave technology is a wizard at streamlining and speeding up reprocessing time with patient care and the utmost safety in mind.